Introduction

The Effluent Water Tank separation efficiency is influenced by its design and its internal structures. To optimize the flow dynamics and separation of residual oil, to optimize the design of internals, and to ensure the effective performance, Computational Fluid Dynamics (CFD) simulation is a powerful tool.

Objective

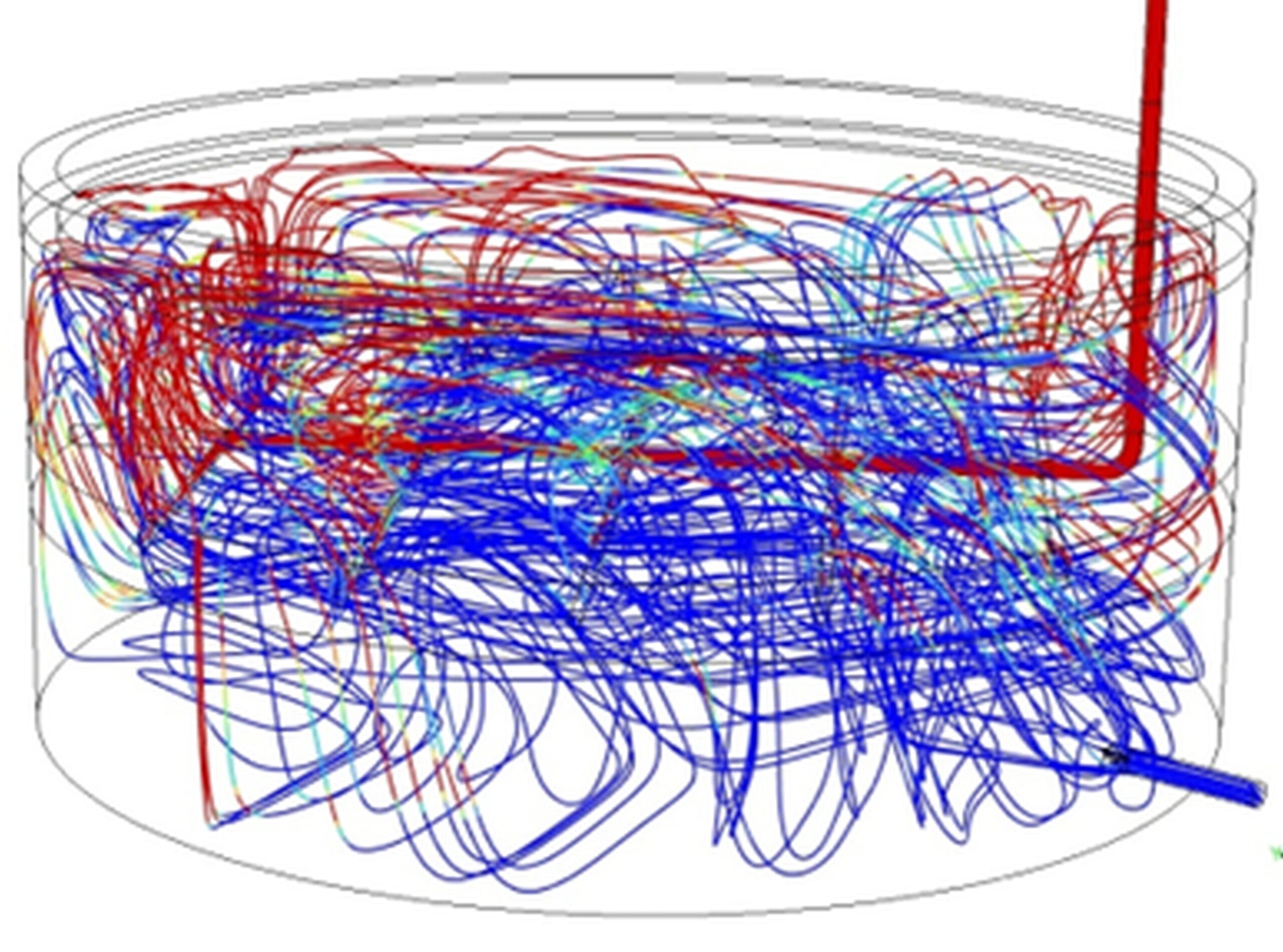

The main objective of the CFD simulation was to study the oil and water separation process and to evaluate the design of the tank internals such that the oil content at the water outlet is less than 100 ppm. Trajectories of water and oil were also to be checked to ensure separation of the two phases.

CFD Analysis

Appropriate Multiphase model was used to accurately predict the separation process. Two phases (water and oil) were considered in the simulation. The CFD analysis included a comprehensive examination of phase distribution, flow regimes that facilitate phase separation, and flow paths to prevent issues such as short-circuiting. CFD analysis was conducted for various internal designs to arrive at the final design. Simulations for various process conditions were also done to ensure that the selected final design is optimum.

Conclusion

The CFD study optimized the inlet distributor design and its location such that oil content at the water outlet is < 50ppm for various process conditions.

CFD Analysis to Optimize the Design of Inlet Distributor for Produced Water Tank

November 7th, 2025

Amarvir Chilka

Our team will answer all your questions. we ensure a quick response.

© T Solutions India. All rights reserved.